11-06-2024

IMS Develops Cost-Effective Plan for Partial Repair of Lining Systems

Partial tank lining failures such as blistering, rust, and deep pits are challenging to repair. Full refurbishment is time-consuming and extremely costly. Neglecting maintenance poses a threat to both substrate protection and cargo safety, while partial repairs without proper workmanship often result in premature coating failures such as detachment.

To reduce maintenance periods and significantly lower costs, IMS carefully surveys and precisely identifies repair areas of lining systems, leveraging years of repair experience, IMS has successfully developed a comprehensive maintenance plan for the partial coating failures of lining systems that greatly reduces both maintenance periods and costs.

Five years ago, IMS provided and supervised partial paint repairs for the cargo tanks of a world-renowned shipowner. Recent inspection results indicate that the condition remains good, with no significant failures detected. The shipowner incurred very limited costs while ensuring the cargo tanks, which have been in service for 10 years, remain in excellent condition.

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

05-05-2024

IMS Successfully Upgrades Hull Coating for Ardmore Tankers Using Advanced Sea-Speed V 10 X Technology

As the authorized on-site technical team by Seacoat LLC, IMS once again utilized the world's most advanced - 100% non-toxic Sea -Speed V 10 X - a hard film Silane ship hull coating system, for the external hull coating upgrade of two chemical tankers from Ardmore Tankers. Upon the completion condition, the AHR was consistently below 20 microns.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

24-04-2024

IMS Secures COT Coating Refurbishment Projects with Renowned Middle Eastern Shipowners

IMS has once again gained the favor of a renowned shipowner from the Middle East. Under IMS’s supervision and guidance, the first chemical tanker successfully completed a tank lining upgrade for all 31 cargo tanks at Yiu Lian Dockyards (Shenzhen) Limited.

Due to IMS's outstanding on-site control during the project, the shipowner has decided to entrust IMS with upcoming dry docking (DD) projects for two chemical tankers starting in July, which will include hull treatment supervision and partial refurbishment supervision of the cargo tank coatings.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

15-04-2024

Successful Completion of Bulk Carrier Coating Upgrades Earns High Praise from Transocean Maritime Agencies

sandblasting and paint upgrade for all cargo holds of the two bulk carriers, Amazon and Artemis I, have been successfully completed within a total repair period of 28 days. This achievement received high praise from Mr. Roland Ledger, the Technical General Manager of European shipowner Transocean Maritime Agencies.

.jpg)

.jpg)

.jpg)

.jpg)

24-03-2024

Continuously Hull Treatment Supervisions for The Esteemed Shipowner Hafnia

Since December 2023 until March 2024, IMS has been continuously engaged by the esteemed shipowner Hafnia as their coating superintendent.

During this period, IMS successfully supervised external hull painting refurbishments/upgrades for four chemical tankers in China and Thailand.

12-03-2024

Driving Growth Through Superior Service and Strategic Partnerships

Due to its outstanding service and commitment to fair customer pricing, IMS has gained increased recognition from more clients. In the three months since the end of 2023, IMS has experienced a significant uptick in orders, with a total of 6-10 projects on hand per month.

By the end of February, garnered the attention of a prominent shipowner from the Middle East, hiring IMS representatives to supervise the complete coating upgrading of 31 COTs as well as hull treatment for the esteemed shipowner.

Furthermore, IMS serves as the exclusive on-site technical inspection team authorized by Seacoat for SEASpeed V 10 X - a hard film Silane ship hull coating system renowned for its 10-year performance guarantee. Having successfully supervised the completion of two vessels with an Average Hull Roughness (AHR) below 20 micrometers, work on the next two ships is scheduled to commence at the end of March or early April.

02-08-2023

IMS has obtained new recognition from an internationally renowned

ship owner

IMS has obtained new recognition from an internationally renowned

ship owner and has successfully completed DD supervision for the

first vessel. The vessel was constructed in 2008 and the DD

was completed on the 25th Mar. 2023 at Yiulian Dockyards (Shekou)

Limited. The entire surface of external hull except for the topside,

has been fully blasted and recoated with Jotun SEAQUANTUM

antifouling coating system.

Based on the positive outcomes that

have been achieved, the owner is continuing to engage with IMS, and

subsequent DD projects were supervised in China and Indonesia during

April, May, June, and July. The next DD is scheduled to commence in

August, and pending the upcoming tank coating refurbishment/upgrade

projects as well.

16-06-2023

IMS gains recognition from renowned bulkcarrier shipowner

The shipowner possesses and operates more than 55 supramax and

ultramax bulk carrier ships. IMS was appointed by the owner as their

coating representative to oversee the coating condition of the hull

and holds, ensuring the best surface treatment and paint

application. The coating refurbishment and upgrade of the ship's

hull and all cargo holds were successfully accomplished on June 15,

2023, at Yiulian Dockyards (Shekou) Limited, and the next dry dock

maintenance is scheduled to begin in August.

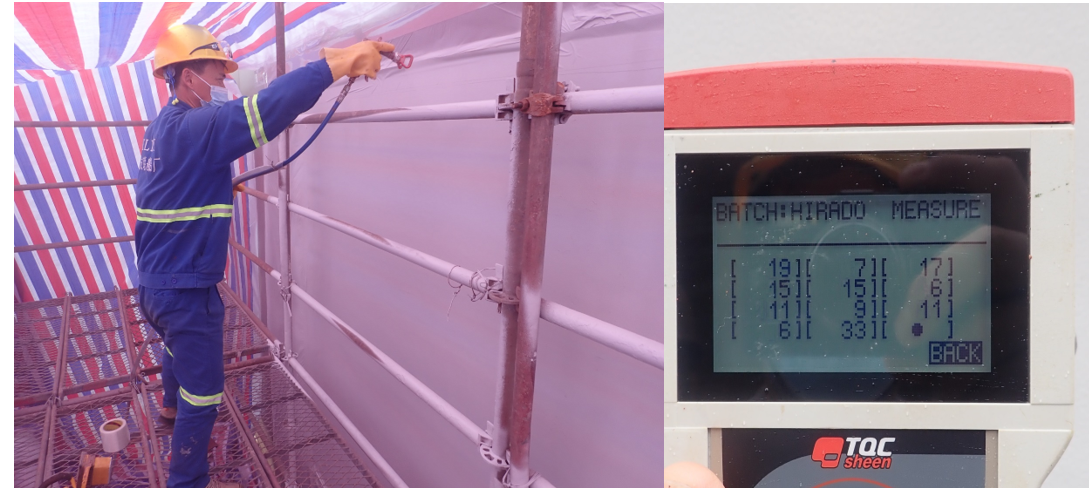

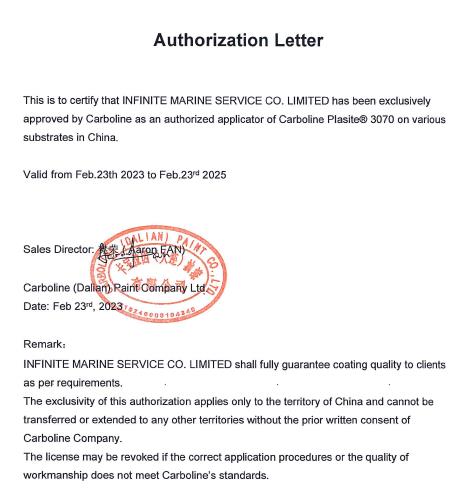

24-02-2023

IMS been awarded Exclusive Applicator of Carboline Plasite® 3070 in

China authorized by Carboline As

Carboline Plasite® 3070 delivers significantly improved product

performance and anti-corrosion resistance, thanks to its high

cross-linked density powered by unique polymer technology, resulting

in more than 150 times as many cross-links as high-temperature

epoxies. Its superior performance is reflected in excellent chemical

resistance, higher temperature resistance and higher resistance to

absorption. and it is widely applied in various industrial

sectors:

Chemical Processing - Tanks, flare tanks, reactor vessels, hazardous

waste hauling, etc.

Paper & Pulp - Digesters, black liquor

tanks, bleaching, etc.

Steel - Pickling tanks, acid storage,

acid waste, neutralization, etc.

Mining - Acid tanks,

scrubbers, etc.

IMS was authorized by Carboline AS on February

23, 2023 as the exclusive applicator for Carboline Plastic 3070 in

China due IMS's reputation, experience and performance in the lining

coating industry.

26-11-2022

IMS successfully supervised test patch for an ultra smooth durable

non-toxic hull coating system, which is the first time that been

applied in China

This coating system applied is completely Non-Toxic and can be

underwater hull cleaned without concern about environmental impact

of toxins or depleting the coating. With the unique coating

application technology that well mastered by IMS Coating Supervisor,

the final condition upon completion the whole system with measured

average surface roughness value of 14.29 microns. Added benefits are

reduction of CII, fuel consumption and GHG emissions up to 12%.

Extremely high idle time capable, tested out to 18 weeks idle with

excellent cleanability.