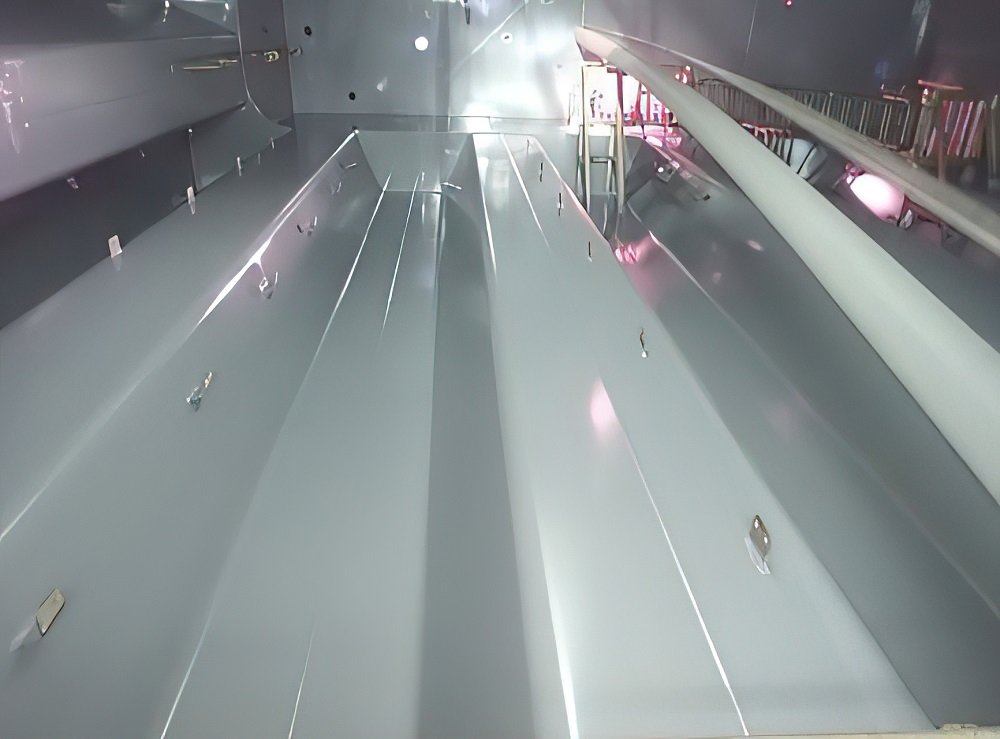

The only way of achieving a good cargo tank coating is by optimum preparation and application standards,thereby maximizing the performance through effective site supervision and control. It is important to note that the workers must obtain instructions for correct working methods in the form of technical guidance and effective communication. For example, specified DFT should be applied by spray painters at the time of full coating application, thereby minimizing the touch-up. Increase in DFT due to repair touch-ups after rejections may cause premature failure on the partial repair areas.Therefore, the final result does not depend on an inspector's acceptance or rejection during inspections, but his ability to correct the defects and deliver a product in accordance with the requirements / standards recommended by the coating manufacturer. It is essential that the owners' coating supervisor possesses not only in-deep theoretical knowledge, but also practical tank lining experiences and foresight to help the contractor find way out to avoid rejections/repeats and unforeseen delays. IMS has a clear advantage on this aspect over others.

Tank coating is a very systematic work. It requires the coating supervisor to be familiar with the properties of the selected coating system and application procedure, as well as the practical aspects of health & safety procedures to handle it, safe way of scaffolding erection / removal, protection of tank fittings, surface preparation, application techniques, material control, correct curing procedure, inspection, maintenance etc. The supervisor should be well conversant with working procedures and able to work with all stake holders as a team, use all the professional knowledge to find optimal solution to resolve any tricky matters encountered on site to ensure that all jobs are carried out under strict quality control. IMS tank coating experts supervise any project in more than 20 distinct steps from arrival condition inspection till completion of all jobs and report preparation with every minute details.

IMS expertise and good coating supervision serves two main purposes for any vessel owner. First, a good coating lining if essential for CPP, chemical and other high purity cargoes where the cargo is carried without any contamination. Second, if the tank surface is smooth and glossy, it aids in tank cleaning when vessel changes cargo grade. Further, a difficult cleaning challenge is encountered in the areas on each staging level and lower hoppers/stools due to incorrect application techniques causing a rough surface. Tank cleaning time and fuel consumption during tank cleaning operation impacts the revenue earning of any vessel in a big way. Further, low fuel consumption means less greenhouse emissions for the vessel.IMS tank coating experts undertake diligently whole-process supervision and guidance during all the phases of the surface preparation, coating application and final inspection.